The goal: A management and monitoring system that is easy to use by a five-digit number of users in a wide variety of functions and covers virtually all operation areas of Holcim, from ordering to delivery and invoicing.

The process: An analysis of the project requirements laid the groundwork for defining the system’s architecture. The ensuing development, integration and configuration of the new software were accompanied by extensive testing to ensure stability and reliability. User training was conducted for a seamless transition to the new system.

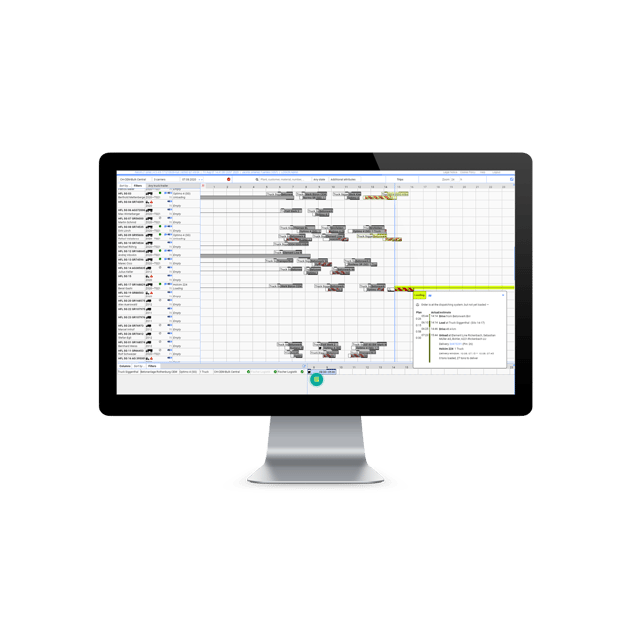

The result: LOGON, or Logistics Online, is a solution that unites data management and accounting systems and monitors the movement and loads of trucks, containers, and silo wagons (including multi-modal shipments). The entirely digital interface in cockpit-style is fully web-based and secures and encompasses ordering, scheduling, dispatching control, delivery as well as re-routings and collects all invoice-relevant parameters later used by the ERP. RFID tags on trucks, containers, wagons, and silos enable composition-verification and avoid unloading material mix/contamination. LOGON was soon expanded to all of Europe, Middle East and Africa, and is also used for railway loading and transport.